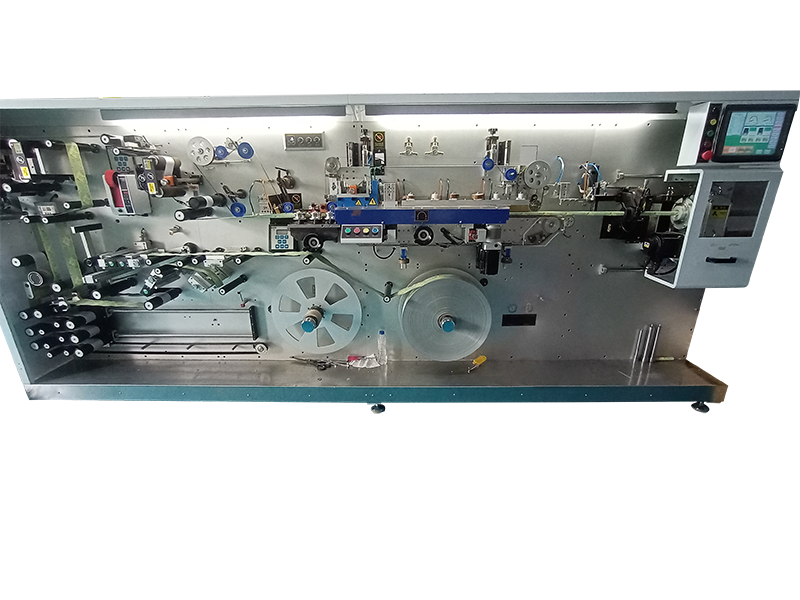

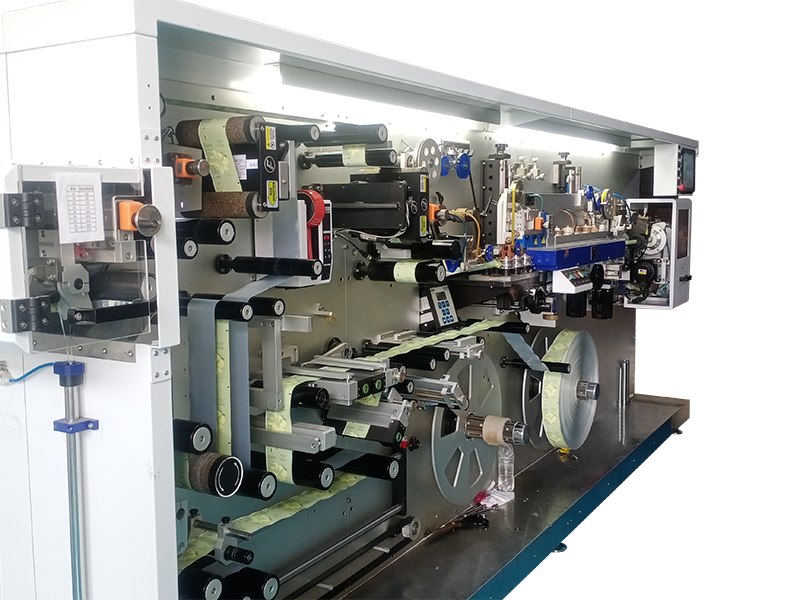

Tube welding machine

Tube welding machine

The plastic tube welding machine transmits the pre printed plastic film, including all plastic film and aluminum-plastic composite film, to the welding area. Due to the large sound resistance at the interface between the two welding areas, local high temperature will be generated. In addition, due to the poor thermal conductivity of the plastic, it can not be distributed in time at the moment and gathered in the welding area, resulting in the rapid melting of the contact surface of the two plastics. After adding a certain pressure, it will be integrated into one. When the ultrasonic stops working, let the pressure continue for some time to solidify and form, so as to form a solid molecular chain to achieve the purpose of welding, and the welding strength can be close to the strength of the raw material.

| Availible films | ABL/PBL/PE |

| Diameter Range | 16mm-55mm |

| Laminate Thickness | 0.25mm-0.45mm |

| Tube Length | 55-210mm |

| Speed | 120-170pcs/minute |

| Operating System | OMRON movement control |

| Specifications | Optics probe |

| YDK pneumatic element | |

| Power Supply | 380V,50HZ |

| Power | 20kW |

| Air Pressure | ≥5Bar |

| Air Consumption | ≥0.5m3 |

| Dimensions | 4800mm*1100mm*1700mm |

| Weight | 2500kg |

Add:No.33-1,Qingpu Village,Xiangping Street,

Add:No.33-1,Qingpu Village,Xiangping Street, Tel:0086-13959260282

Tel:0086-13959260282 Email:info@tsingmachine.com

Email:info@tsingmachine.com